- 電化學相關(5)

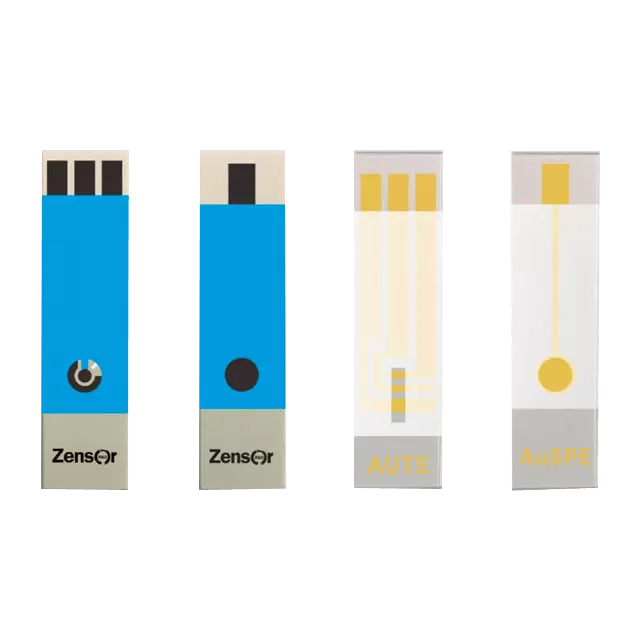

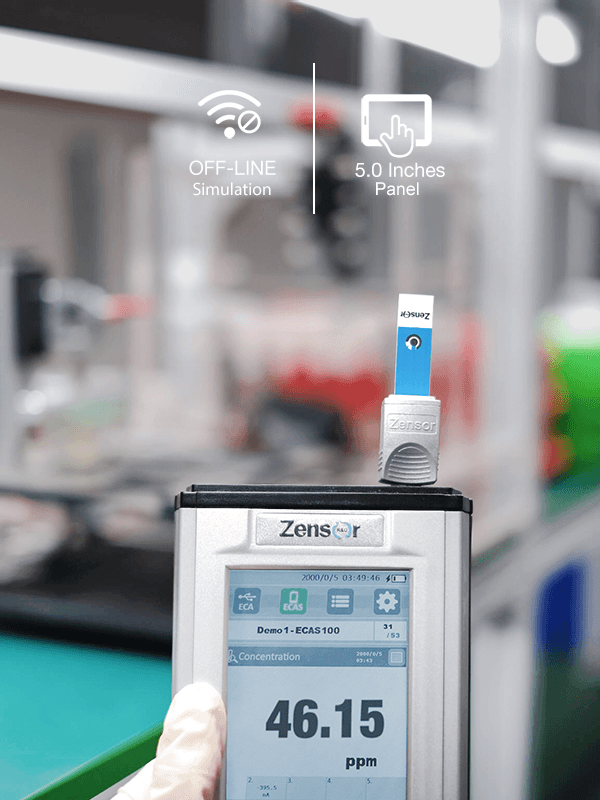

- 化學感測器實擬分析儀 - Zensor Simulator(4)

- ECAS100

- ACIP100

- Optical + EC

- 電化學偵測器 - Zensor ECD(1)

- SF100

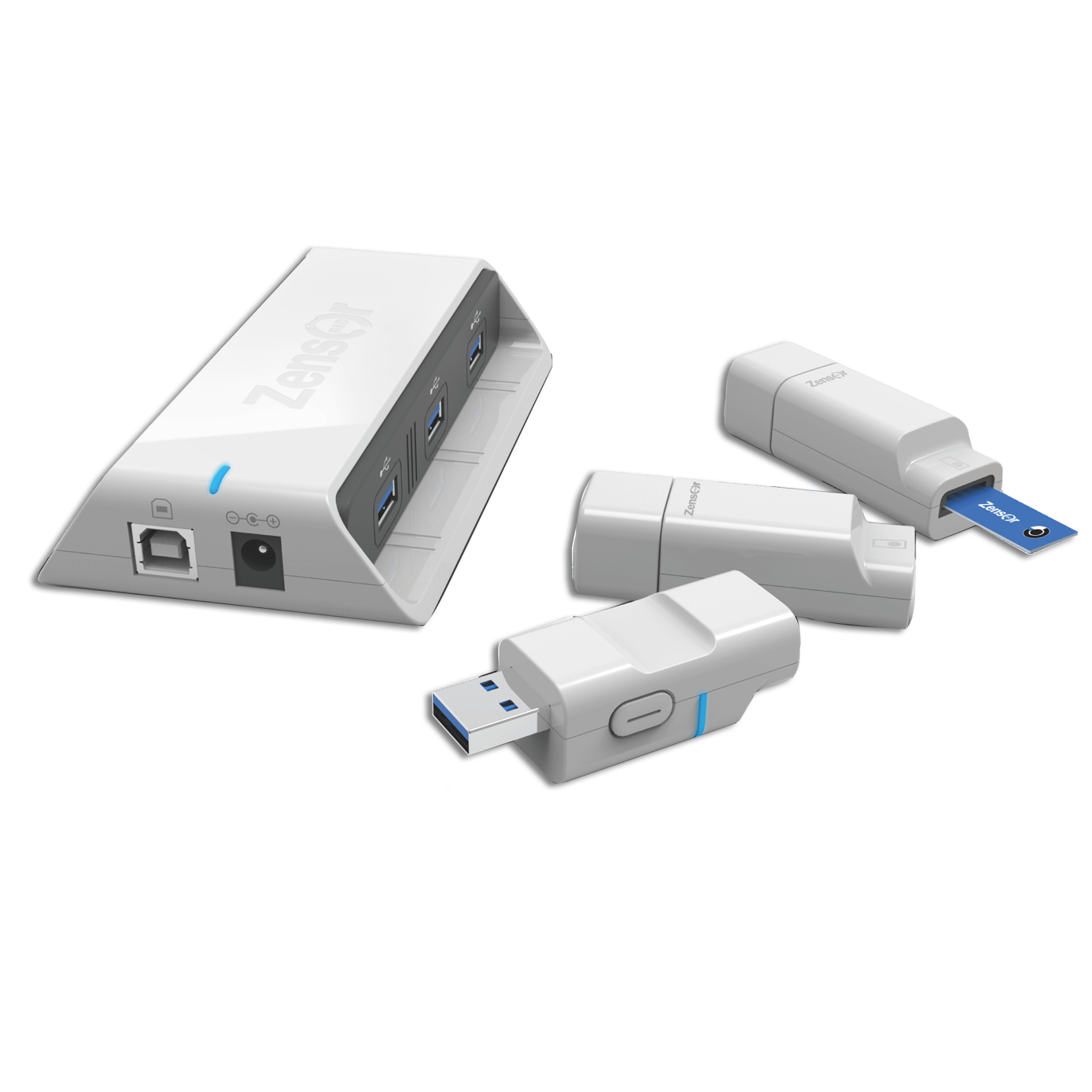

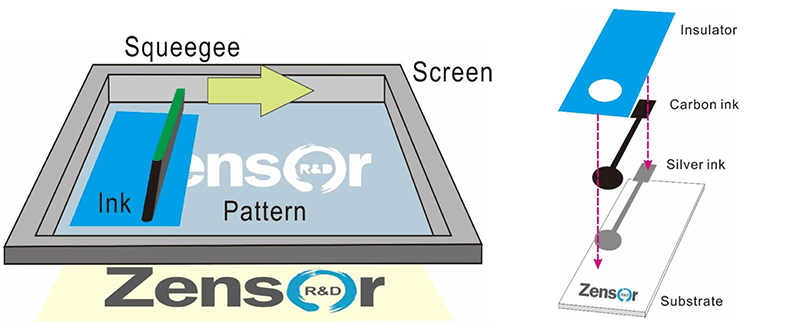

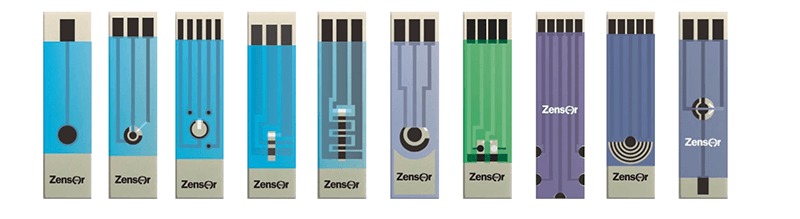

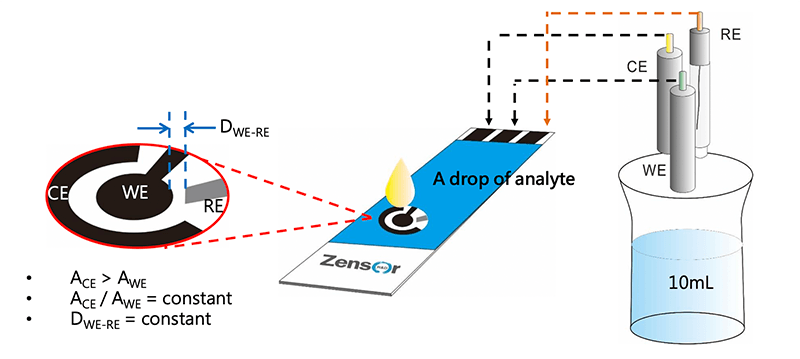

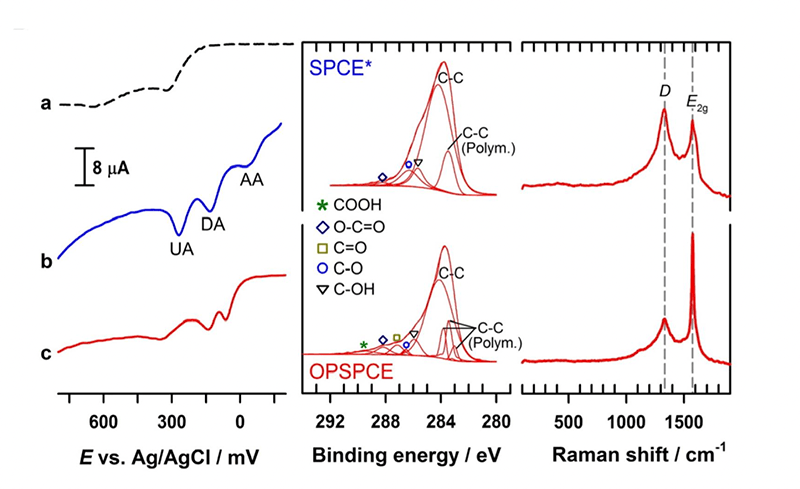

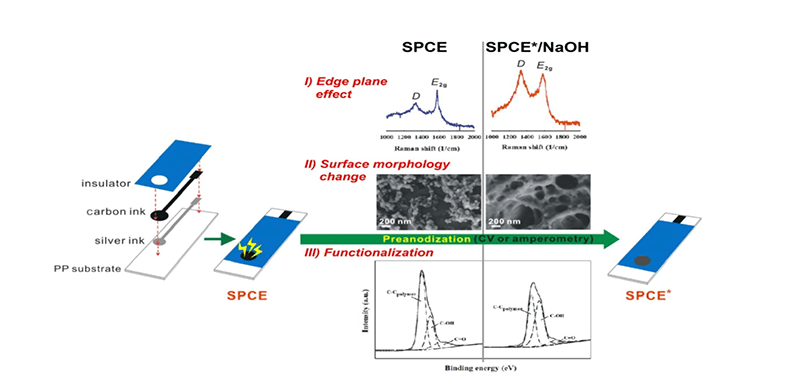

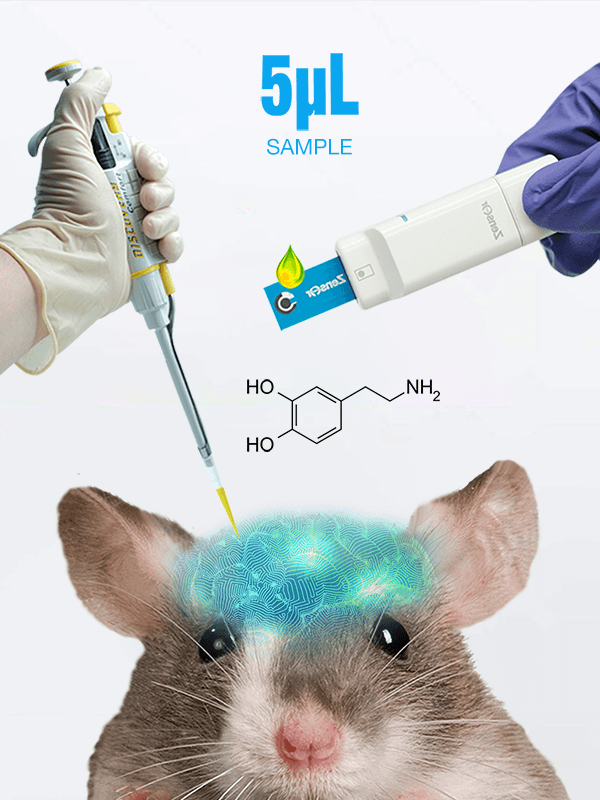

- 網版印刷電極 - Zensor SPE(7)

- 電極客製服務

- TE100 碳三電極

- SE100 碳單電極

- AG100 銀電極

- AUSE100 金電極

- SAUTE100 金電極

- AUTE200 金電極

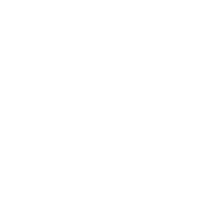

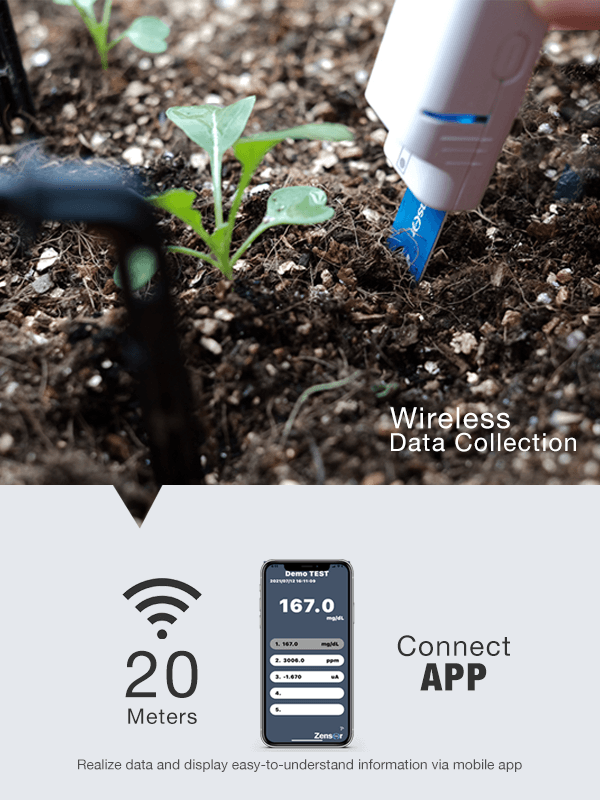

- 無線&多通道恆電位儀 / 電化學分析儀 - Zensor MCP(2)

- ECWP100

- MCP100

- 其他產品(3)

- CS100

- CM100

- CT100

- 化學感測器實擬分析儀 - Zensor Simulator(4)

- 相關公司(8)